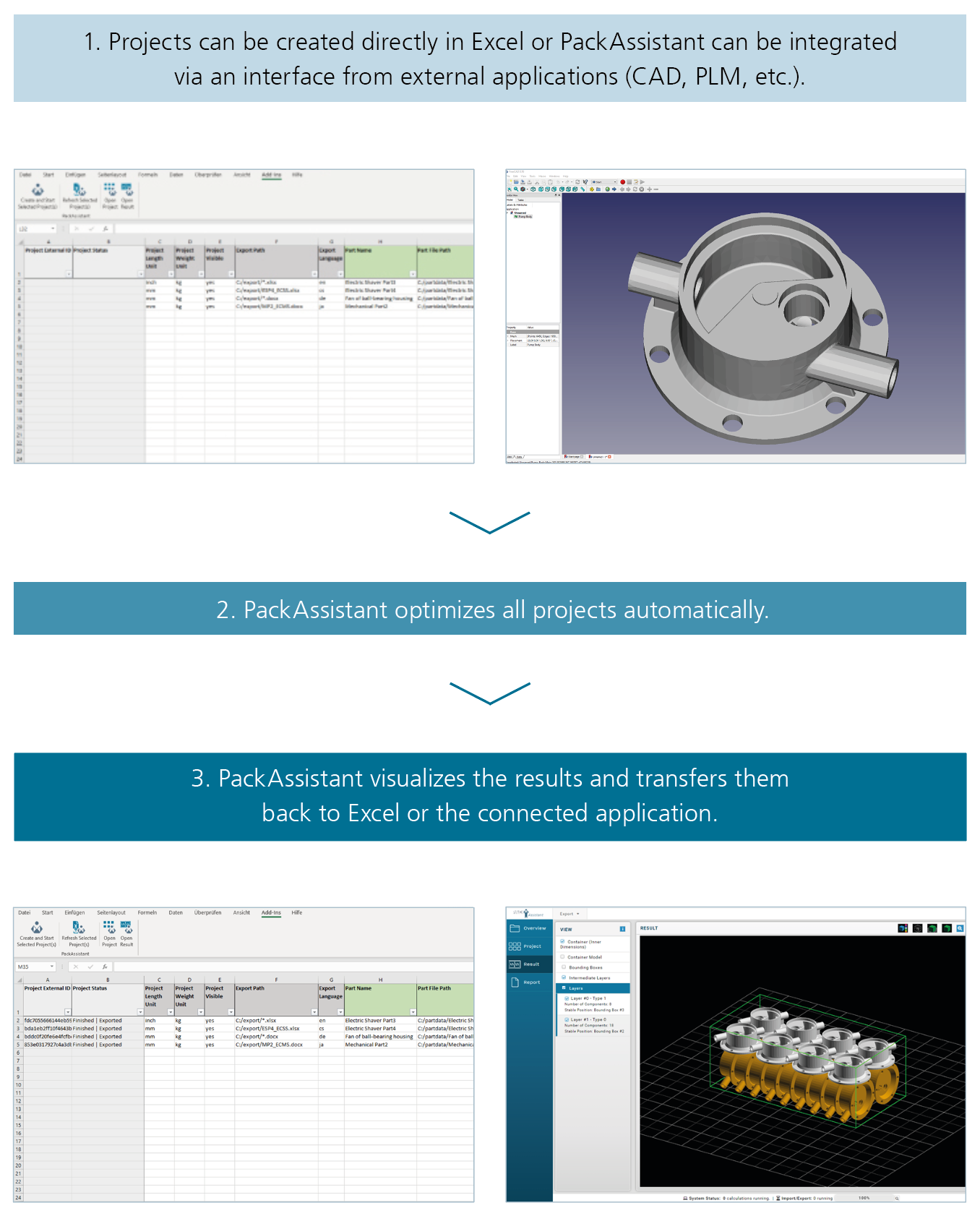

One software – many options

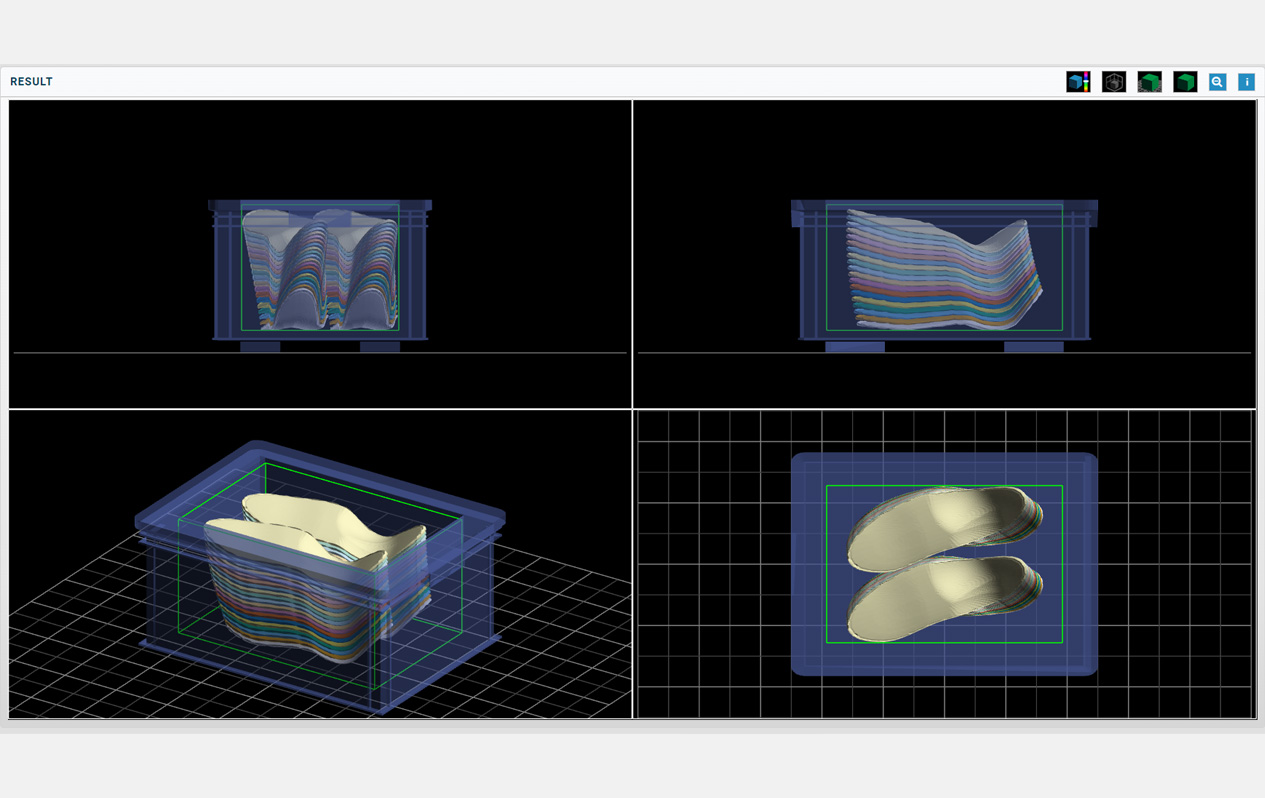

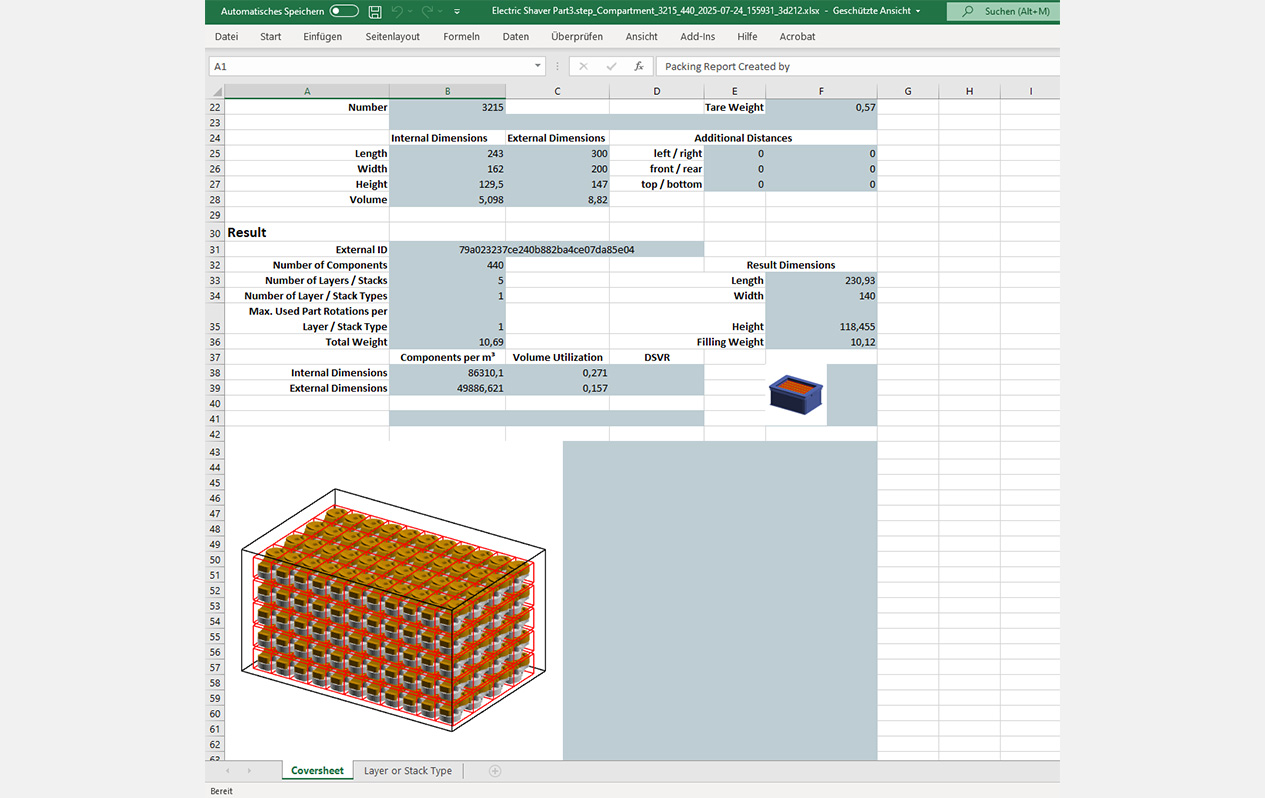

PackAssistant supports a wide range of packaging types, described in the sections below. It also offers advanced functions for customer-specific solutions, including:

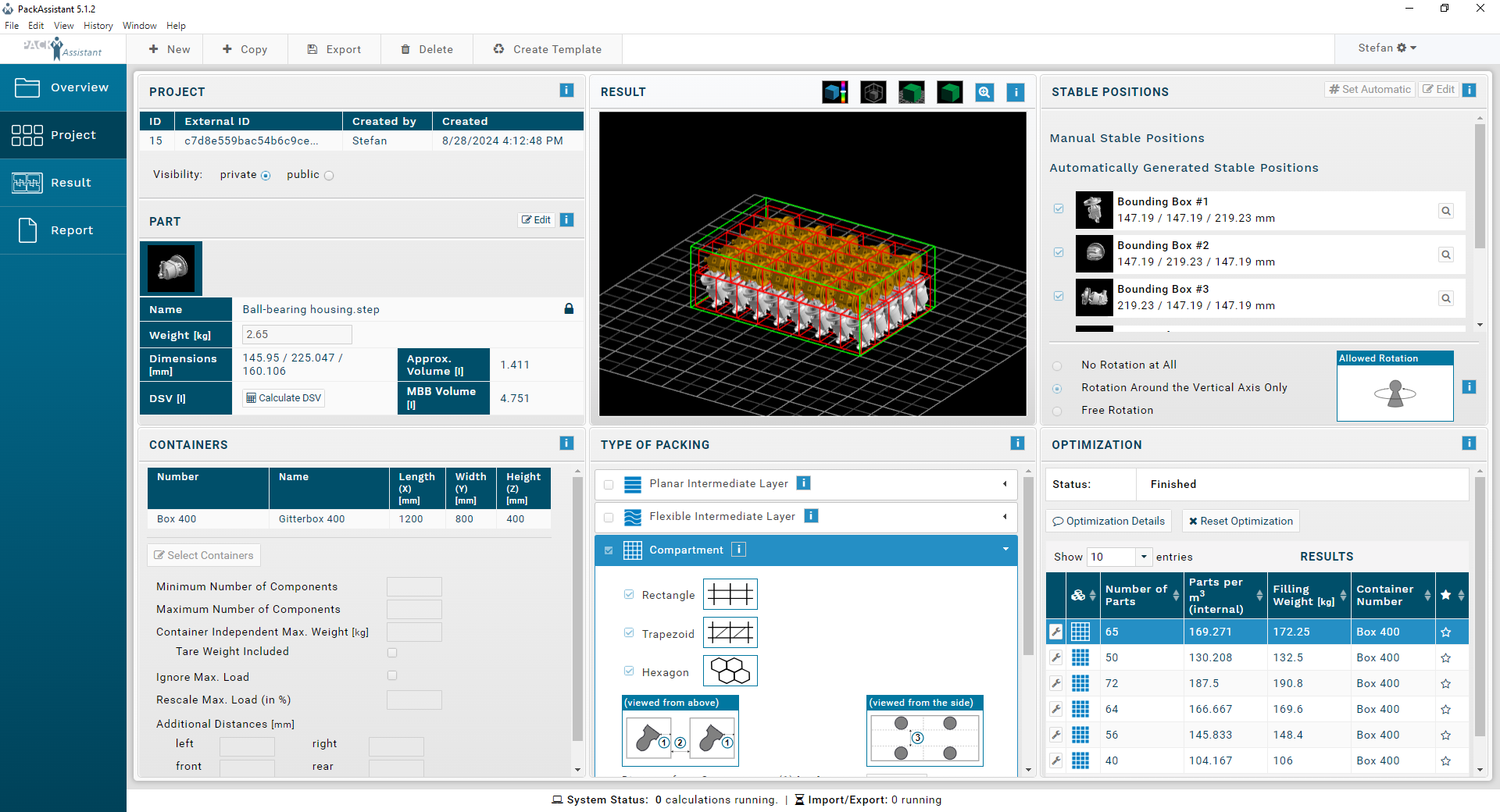

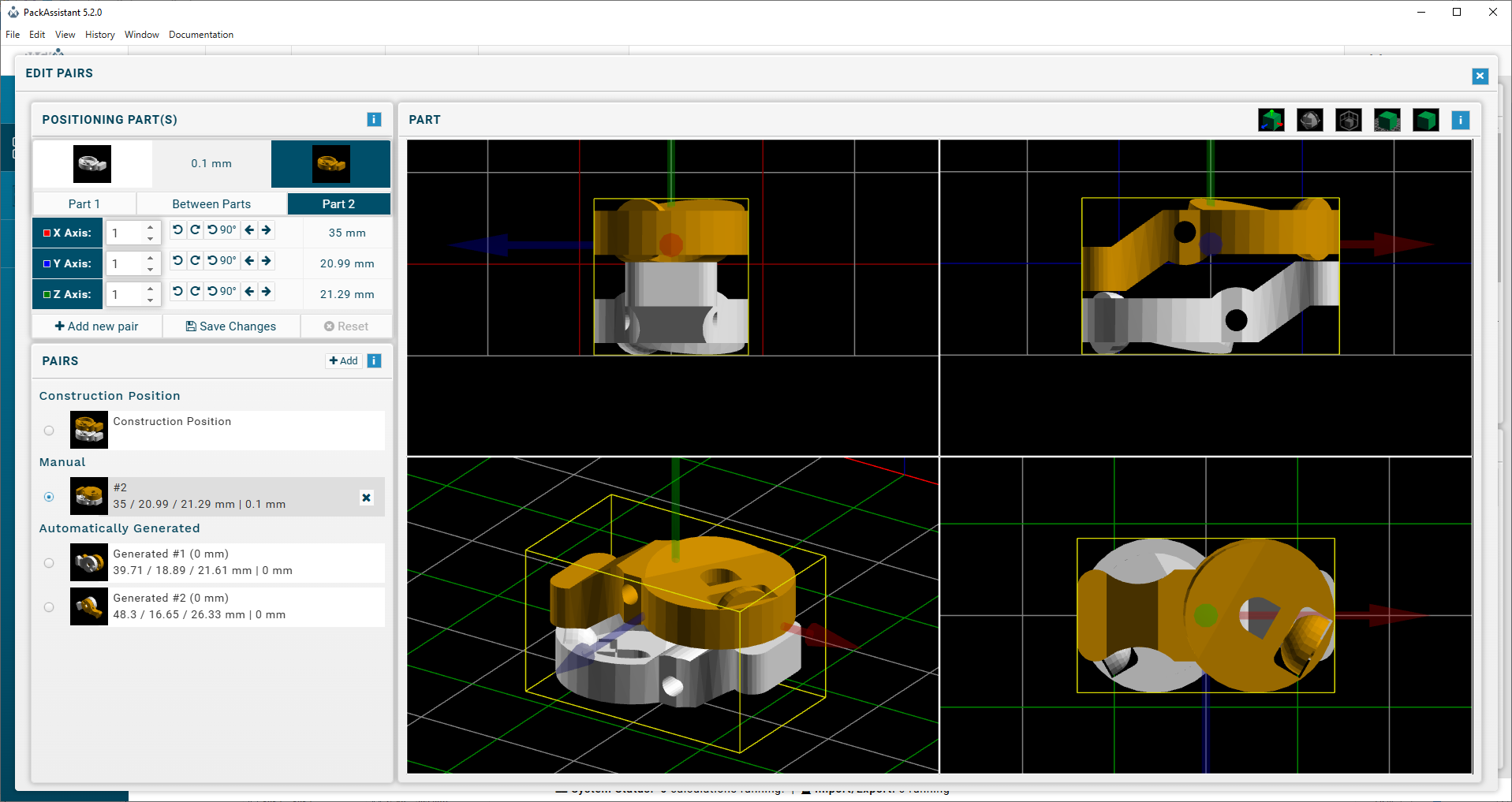

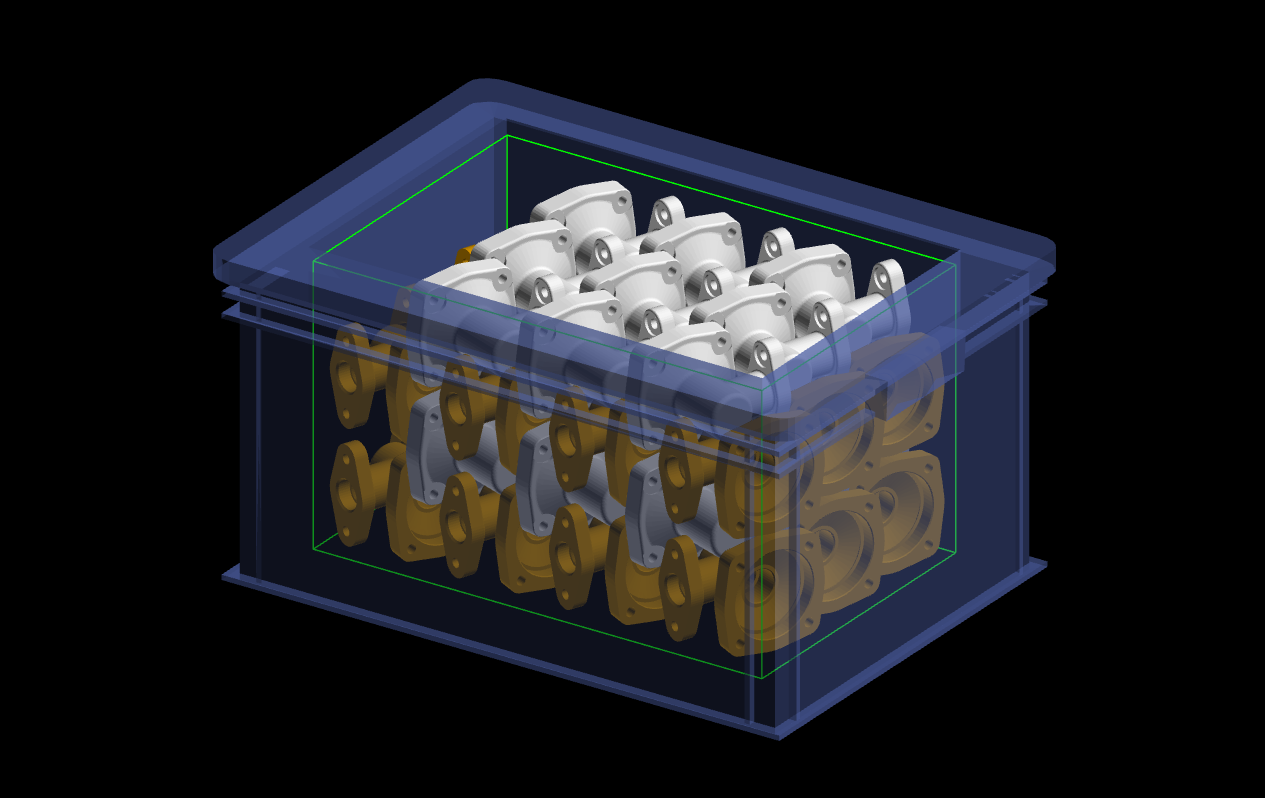

- Possibility to select the minimum distance between parts, the container base, walls, and compartments.

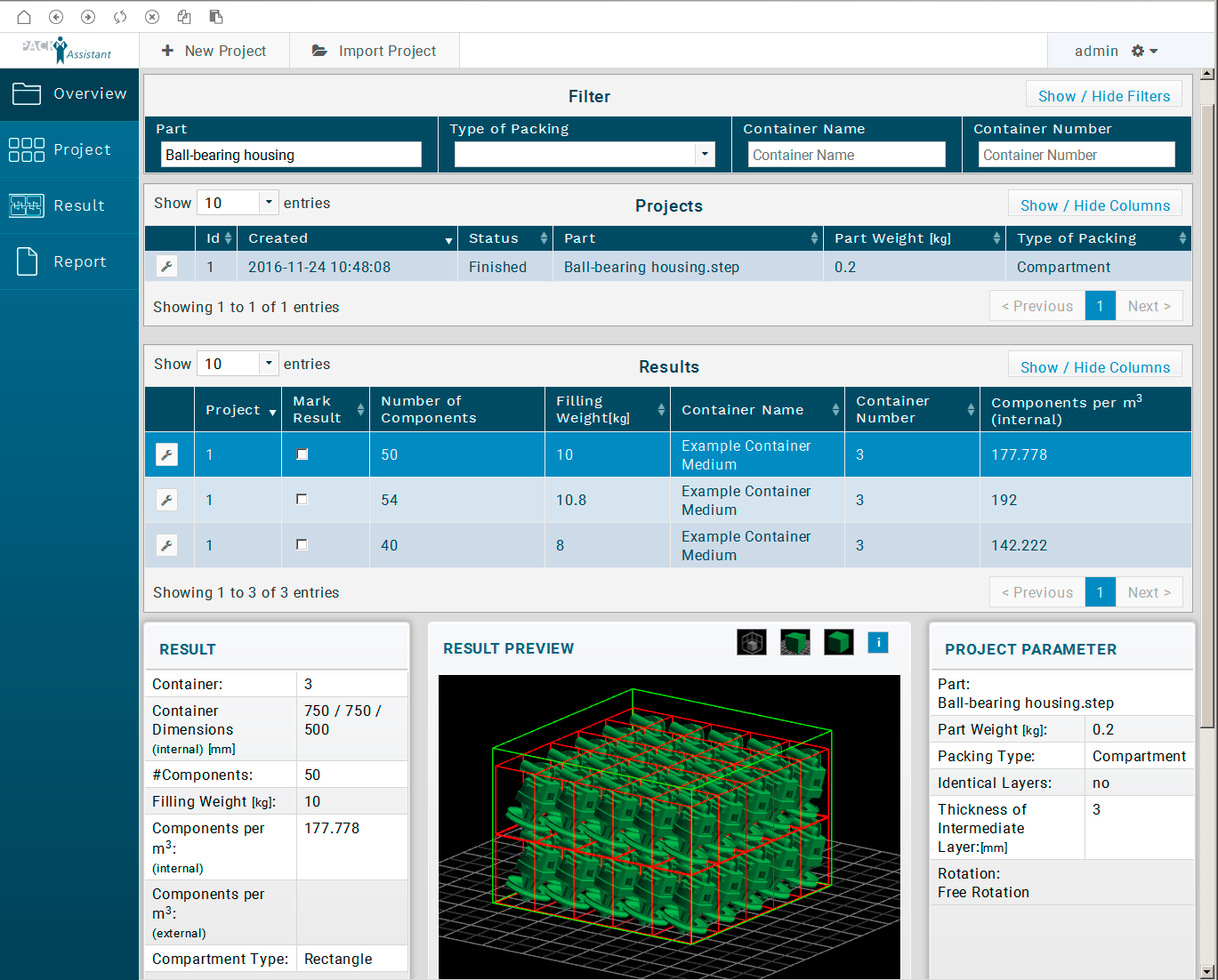

- Adherence to the maximum load of the container.

- To facilitate the container’s stability, it is possible to define stable positions for the parts.

- Calculation of the minimum volume bounding box of a single part.

- Automatic choice of an appropriate container from a list.

- Based on the 3D data, an approximated center of gravity of the part is displayed in the 3D view.